Industrial vacuum cleaners often feature advanced filtration systems to handle the collection of fine particles and hazardous materials. They may incorporate HEPA (High-Efficiency Particulate Air) filters or specialized filters to meet specific industry regulations or requirements. As the filter is the essential consumable parts of a vacuum cleaner, many customers are very care about how often they should replace a new filter.

The frequency of filter changes in an industrial vacuum cleaner depends on several factors, including the type of filter used, the nature of the materials being vacuumed, and the operating conditions. While specific guidelines may vary depending on the manufacturer and model, here are some general indications that suggest it’s time to change the filter in an industrial vacuum cleaner:

1.Reduced Suction Power: If you notice a significant decrease in suction power or airflow, it may indicate that the filter is clogged or saturated. Reduced suction indicates that the filter is no longer effectively capturing and retaining particles, and it may be time for a replacement.

2.Visual Inspection and Performance: Regularly inspect the filters for signs of damage, blockages, or excessive buildup of debris. If the filter appears torn, heavily soiled, or damaged, it should be replaced promptly. Additionally, if you notice dust escaping from the vacuum, or odors during operation, it may indicate the need for filter replacement.

3.Usage and Operating Conditions: The frequency of filter replacement can be influenced by the volume and type of materials being vacuumed, as well as the operating conditions of the environment. If the vacuum cleaner is regularly used in demanding or dusty environments, filters may need to be replaced more frequently compared to less demanding applications.

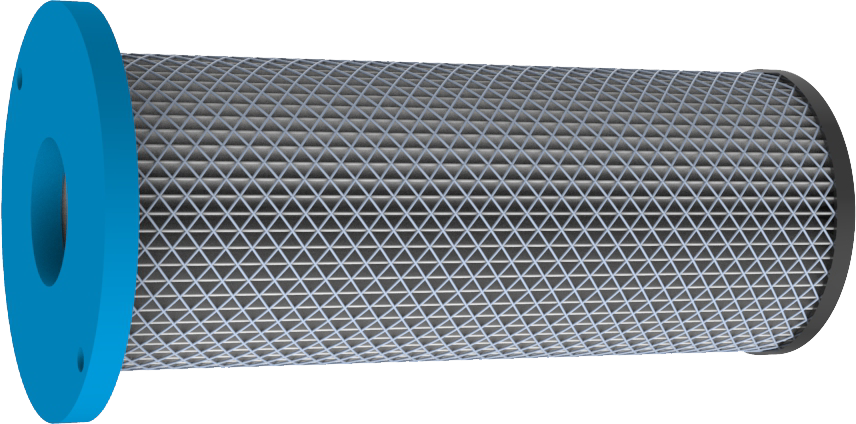

4.Filter Type: The type of filter being used in the industrial vacuum cleaner can also impact the replacement frequency. Different filters have varying capacities and efficiencies. For example, disposable filters may need to be replaced more frequently compared to reusable or washable filters. HEPA (High-Efficiency Particulate Air) filters, which are commonly used in industrial settings requiring high levels of filtration, may have specific guidelines for replacement based on their efficiency and particle size retention capabilities.

5.Manufacturer’s Recommendations: The manufacturer of the industrial vacuum cleaner typically provides guidelines on filter replacement intervals based on their specific product and its intended usage. These recommendations should be followed for optimal performance and longevity of the vacuum cleaner. Consult the user manual or contact the manufacturer directly for their specific recommendations.

It’s important to note that some industrial vacuum cleaners have multiple filters, such as pre-filters and main filters, which may have different replacement schedules. Therefore, it’s essential to refer to the user manual or contact the manufacturer for specific guidance on filter replacement for your particular industrial vacuum cleaner model.

Post time: May-20-2023